Jackson fully embraces new technology and innovations that improve and enhance the construction delivery process. Our systems offer opportunities to maximize safety and quality, while minimizing schedule and costs.

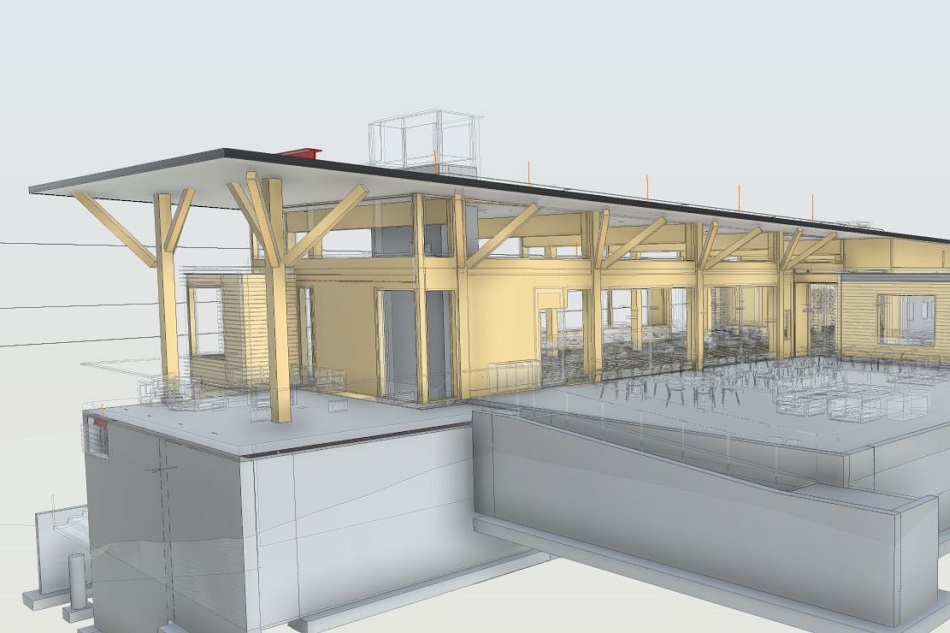

Building Information Modeling

BIM provides continuous coordination between architectural, structural, and Mechanical/Electrical/Plumbing (M/E/P) plans and drawings throughout all design phases. This allows Jackson project managers and superintendents to identify potential problems early to prevent additional field work that would increase costs. Additionally, if obstacles occur during construction phase, changes to drawings can be made quickly and transmitted to the field in real-time.

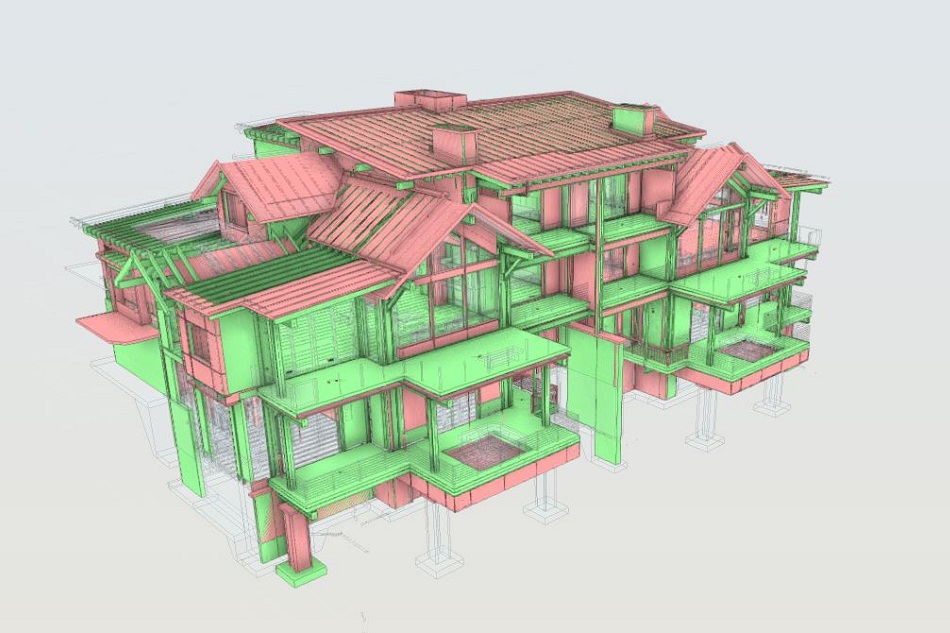

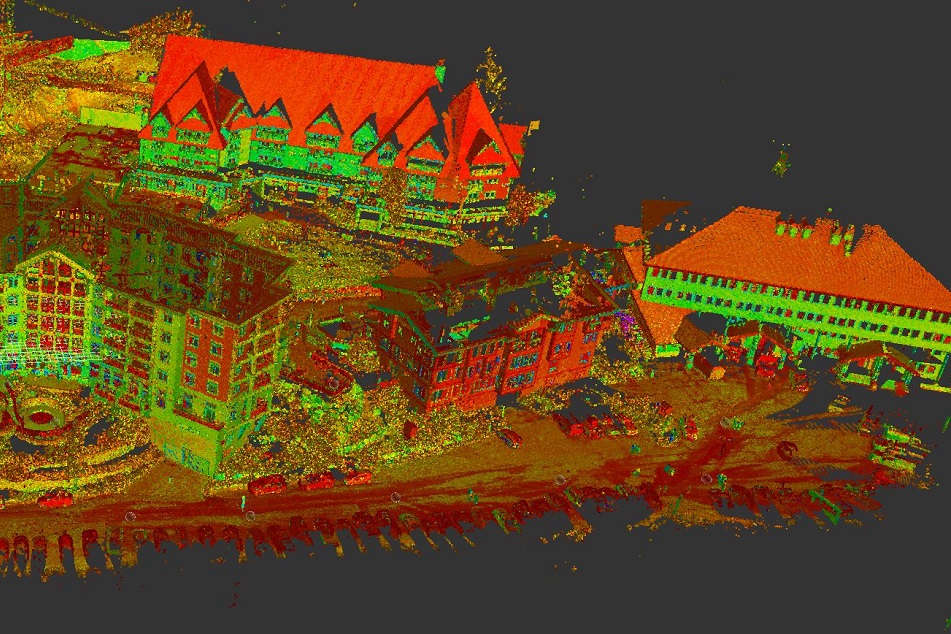

Virtual Design & Construction

VDC technology mitigates risk through precision in prefabricating materials, modeling the construction sequence, confirming the building system, cost analysis, confirming position and performance of M/E/P controls and systems to ensure the long-term sustainability and/or efficiency of the facility.

Prefabrication

When suppliers can precisely prefabricate with 3-D modeling all necessary materials for a project, Jackson gets the correct materials delivered on time or in advance of the construction sequence, which keeps the project on-time and on-budget. However, if the parts don’t fit, we can’t build them into the structure. Reordering materials can negatively impact the construction schedule and dramatically increase costs.

Construction Sequence

VDC technology allows Jackson to model the chronology in which the project is planned to be built. Since the program can translate all of the activities in real-time and bring visibility to actual sequencing before construction has commenced, Jackson is able to identify and mitigate any obstacles before they occur.

Building Systems

Better cost information can optimize material combinations to meet cost objectives – for example, the project team may proportion building skin materials based on cost. One building system could be more optimal for construction schedule compression, or another system could diminish future operational and maintenance costs to meet sustainability goals.

Capital Investment Cost vs. Operating Costs

VDC modeling can visually translate the trade-off of Capital Costs vs. operating costs. Often, two different entities or departments own or manage the capital cost and operating budget of the facility, and each remain focused on their respective costs. Over the life of the facility the operating costs are typically higher than the initial capital investment. With VDC modeling Jackson offers clients an opportunity to compare, or justify, the capital investment with projected operating costs.

Controls

Typically, there are M/E/P control options available for any project. Selecting the “right” combination of manual and automated controls is critical to the project’s success in terms of the user’s and operator’s long-term satisfaction with the facility.